Laboratory Non-Destructive Testing Services

Laboratory Inspection & Testing

MISTRAS offers in-house laboratory testing for newly-fabricated components. These services are most commonly offered to clients in the oil & gas and aerospace industries, but can extend to any customer with a need to inspect newly-fabricated parts.

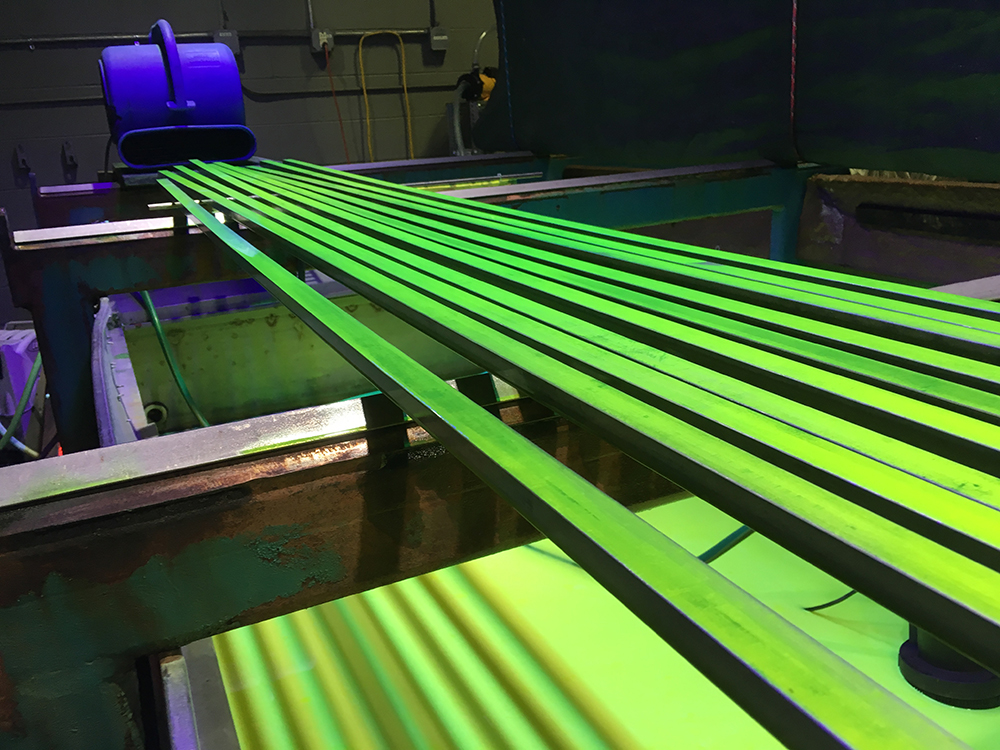

We primarily perform radiographic (RT), penetrant (PT), magnetic particle (MT), and Ultrasonic Testing (UT) at our labs.

Aerospace Lab Testing Services

There are few industries in which the safe and reliable operation of equipment is more essential than the aerospace industry. Aircraft engine and composite failure can have catastrophic consequences, so MISTRAS provides in-house lab testing to ensure the safety of aircraft components.

MISRTAS’ in-house lab testing conforms to a variety of prime manufacturer certifications throughout Canada, including some of the largest names in the industry (see the full list here).

We perform testing on the following aerospace components, with competitive turnaround times and experienced technicians:

- Jet engines

- Structural components

- Round and flat bars

- Round and flat billets

- Plates

- Extrusions

- Rough machined forgings

- Rotating engine fans

- Turbine disks

Oil & Gas Lab Testing Services

We perform in-house lab inspections and testing on newly-fabricated components in the oil & gas industry, most commonly on spooling, compressor bottles, and large vessels. We offer multiple RT bunkers, and also perform Hardness Testing (HT) and Positive Material Identification (PMT).

Common applications of our oil & gas lab testing services include:

-

Welded Components: Lack of Fusion, Incomplete Penetration, Slag Inclusions, Porosity, Undercut, Cracks

-

Castings: Shrinkage, Tears, Inclusions, Gas Pockets, Cracks

-

Raw Materials and Machined Parts: Laminations, Surface Cracking, Corrosion

Lab Test Reporting

Our reporting system was developed in-house, and allows for our clients to mine deeper into data than other systems. It enables clients to create statistical reports in order to compare repair rates between welders, jobs, time frames, and a multitude of other options. Clients are able to pull up past inspections, reports as well as review all inspections that were performed on any given job. The reporting system also allows for real-time invoicing, as all of the billing is coded as soon as the report is printed.